- Hign-concerned Chemical: None

- is_customized: No

- Pattern: Vegetable-Tanned

- Thickness: 4.5-6.5oz (1.8-2.6mm),you could choose the thickness you want

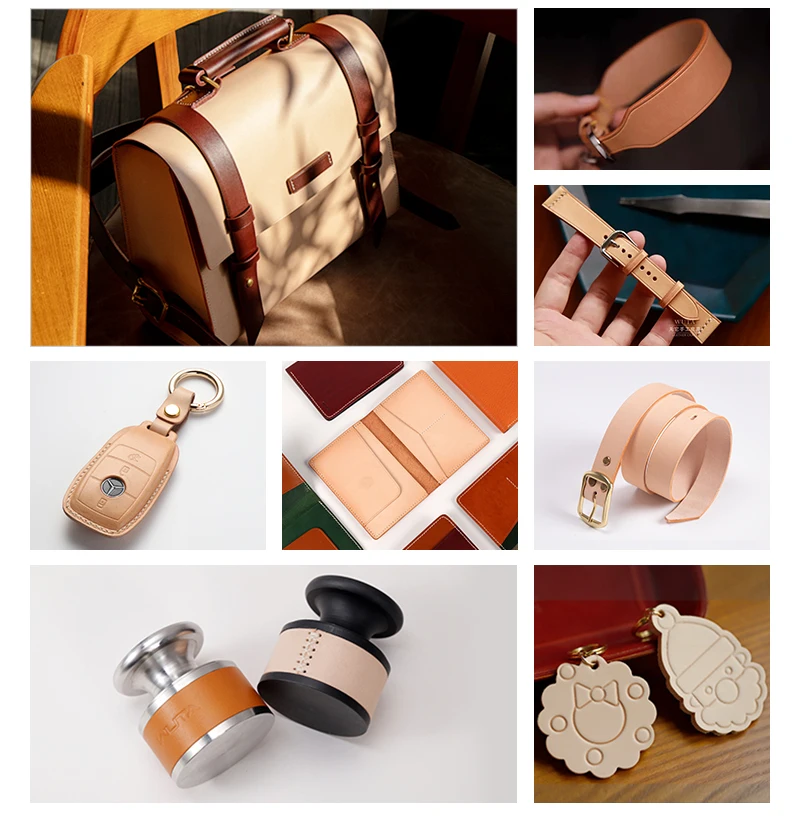

- Use: Handbag,Belt,cases,holster,knife sheaths, wristbands and other various handcraft

- Material: Cow Skin

- Type: Grain

- Brand Name: WUTA

- Origin: Mainland China

- Size: Various sizes available

- Color: 9 colors available

About WUTA Leather.

We are committed to provide the best service and products to handwork people. In additional to acrylic template, we sell other high quality craft tools, and leather.

Vegetable tanned leather tanning agent is a plant made of leather tanning, and therefore it does not contain hazardous substances on the human body, is a kind of direct contact with the skin, green leather, harmless to human body.

Package:

includes 1 x leather piece . the size depend on what you choose.

Description:

Name: Drum dyed vegetable tanned leather

Brand: WUTA

Material: First Layer Cow Skin

Process/Finishing: Vegetable-Tanned

Type: Full grain, made in China

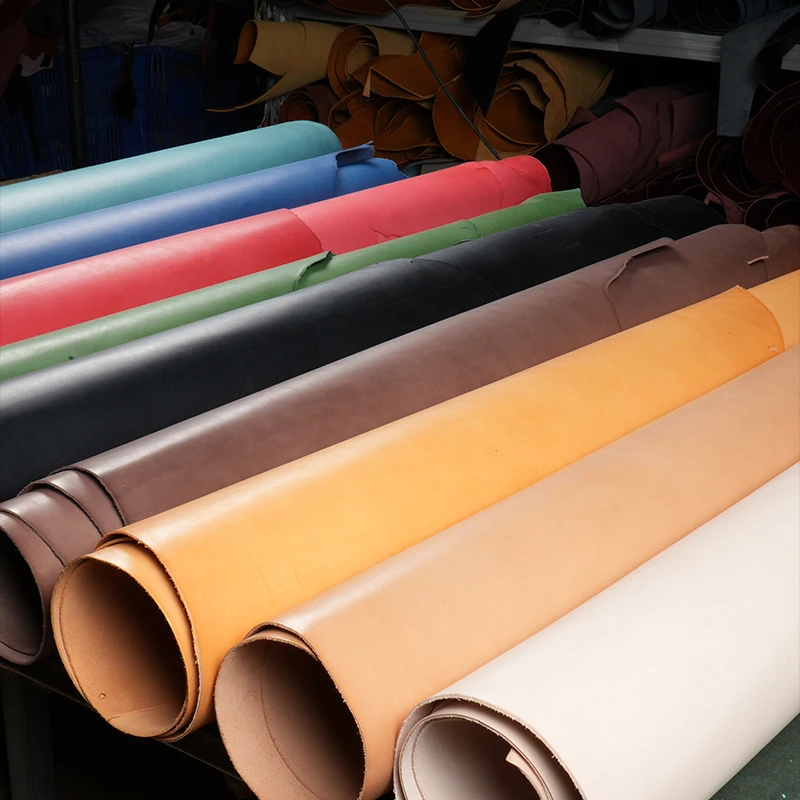

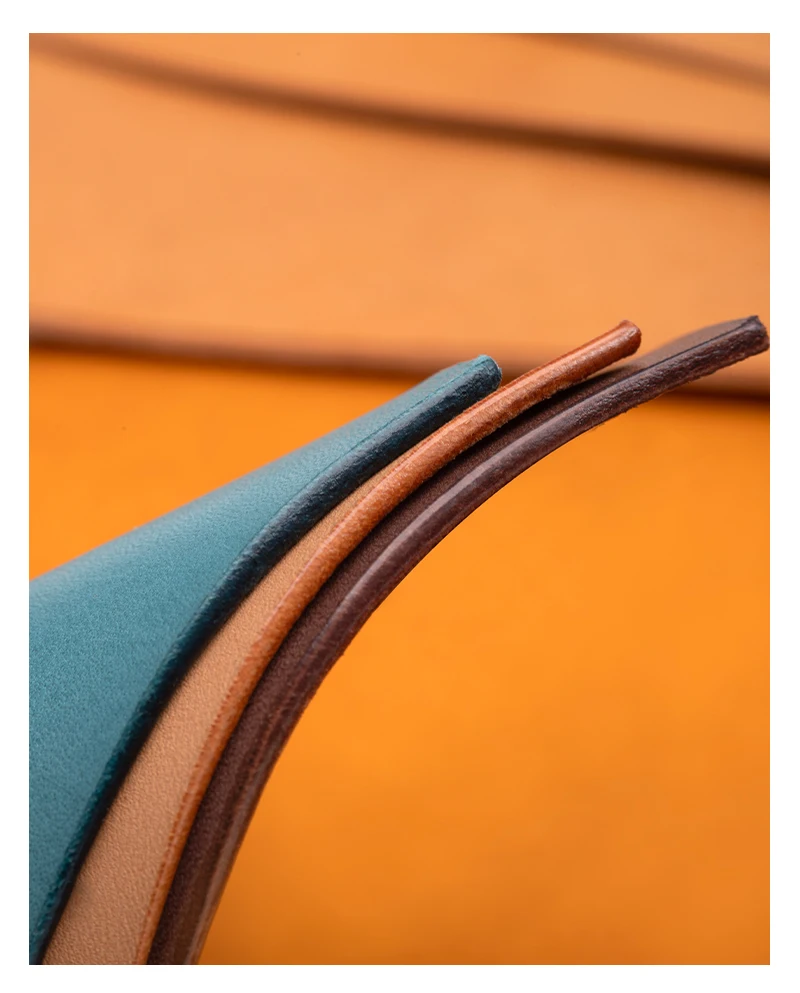

Color: 9 colors available, Natural, Black, Oak brown, Sunset yellow, Mocha coffee, Royal blue, Turquoise blue, Red, Green

Temper: Firm and smooth

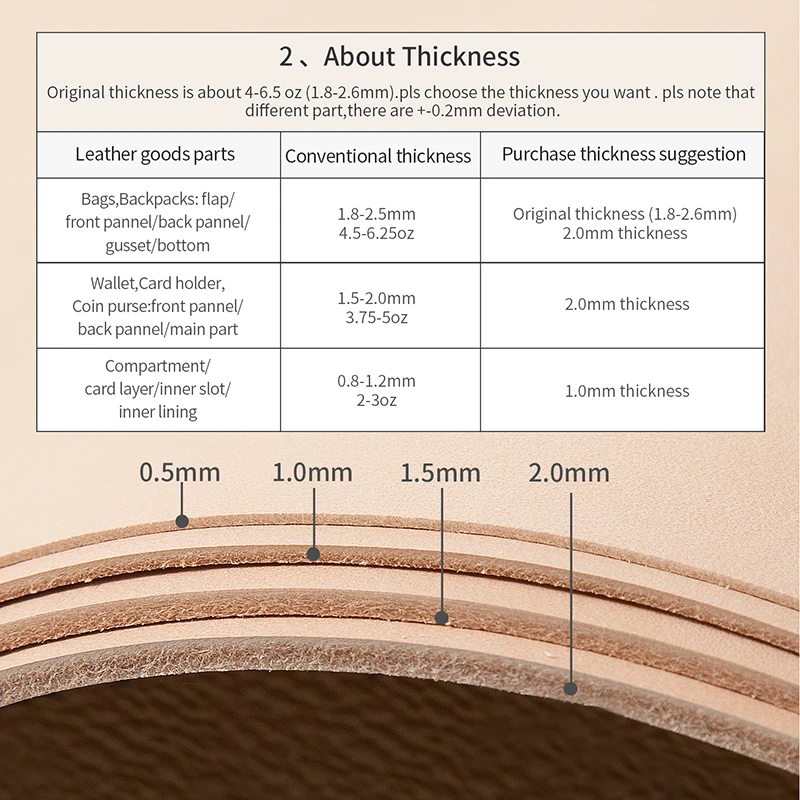

About the thickness:

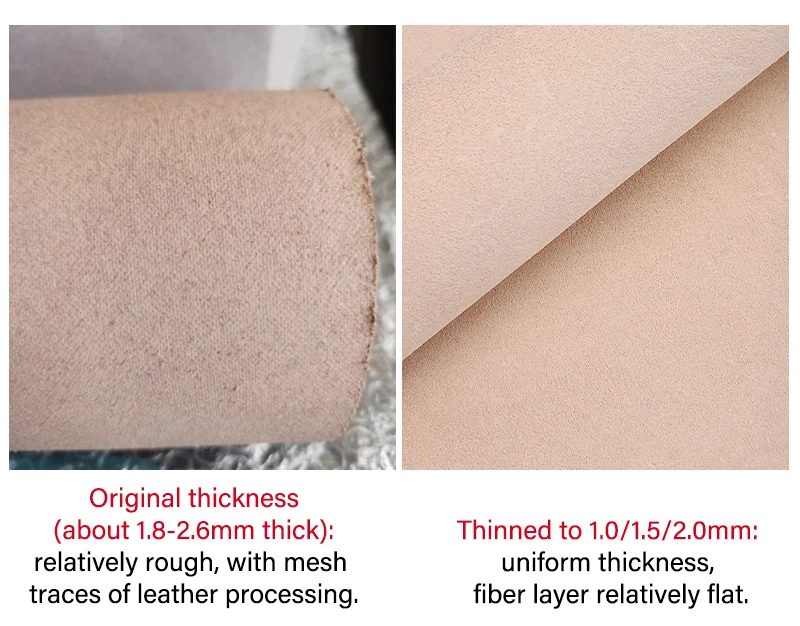

Approximately thickness: original thickness is about 4.5-6.5 oz (1.8-2.6mm). pls note that different part,there are +-0.2mm deviation. if you have specially requirement of thickness ,please remark the requirement when purchase.

Free skiving service: If you need thinner thickness,please leave a message for us when you order, we can skive the leather to the thickness you need(with machine) .Leather can be skived to 1.0mm thick or above.

The real thickness of the items may be slightly different from different batch productions.Even with a piece of leather, different parts, the thickness may also have differences.

Features:

—Genuine First Layer vegetable tanned tooling leather with natural leather smell.

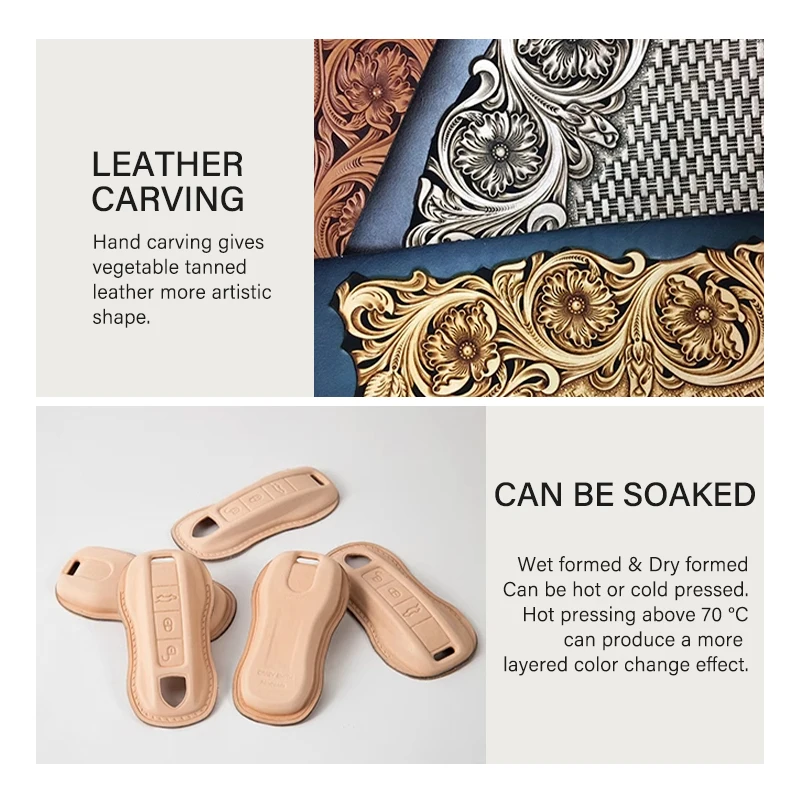

—full grain(not split) untreated leather, there are many visible pores on the smooth surface–quality assurance of top genuine leather. IT can be soaked and wet formed.Can be dying,carved, tooled, embossed,and are great for engraving with laser engraver.

—-Water drum dyed, the color is transparent, stable and firm.the leather surface finish is no coating.

Introduction to dyeing process: Water dyeing is the most expensive and highest quality dyeing process. the large water drum is used to soak and dye the leather. The finished leather has high elasticity and good color stability. but the production flexibility is low, because a single dyeing process requires more than 2,000 square feet. and the cost of aqueous dyes is many times higher than that of powder dyes, and the dye consumption is greater.

—High fiber density, slightly firm & rich oil content,smooth on grain side and consistent on flesh side. Filled with rich oil during manufacturing process to make it firm but not hard and won’t “crack” if folded. These pieces can be great to use on projects such ashandmade wallet, purse, notebook, coasters, any kind of straps, holsters, knife sheaths, pet collars,pyrography and so much more.

—Italian origin – imported leather embryos + Italian vegetable tanning material + Italian leather technology + leather engineer who has worked in Italy for 12 years. From the skin to the smell, it is full of Italian.

How to identify the quality of vegetable tanned leather

Water drum dyed and without any surface treatment and coating, free from artificial alteration.

Handmade waxed. Full-grain colored embryo + Italian fog wax liquid = high-quality fog waxed leather

PRODUCT DETAILS

The leather surface finish is untreated and no coating, free from artificial alteration.

Retains the natural character and texture of cowhide. Can be soaked and wet formed.Can be carved, tooled, embossed..give more possibilities to your handwork.

Italian origin – imported leather embryos + Italian vegetable tanning material + Italian leather technology + leather engineer who has worked in Italy for 12 years. From the skin to the smell, it is full of Italian.

Water drum dyed and without surface treatment.

The color is transparent, stable and firm.You can use it as a base color,then stain again.

Introduction to dyeing process:

Water dyeing is the most expensive and highest quality dyeing process. the large water drum is used to soak and dye the leather. The finished leather has high elasticity and good color stability. but the production flexibility is low, because a single dyeing process requires more than 2,000 square feet. and the cost of aqueous dyes is many times higher than that of powder dyes, and the dye consumption is greater.

Ultrasonic powder dyeing is a common small batch dyeing method with low cost and flexible production. The minimum order is 300 square feet. but the color uniformity is low, the color fastness is low, and the leather dries out.So we don’t use this dyeing method.

The leather surface is clean and smooth.

The leather surface finish is exceptionally unique: untreated and free from artificial alteration,retains the natural character and texture of the hide.

Full grain untreated cowhide, with clearly visible pores.

Quality assurance of top genuine leather.With the Natural animal pores of the material intact, full grain leather is more breathable.

The leather fiber is strength,durability.

Rich in oil and elasticity, easy to edge finish only with water.

High fiber density,the back side is flat and burr-free.

The fiber is tight and not easy to shed chips.

The leather flesh side (bottom)

–Original thickness (about 1.8-2.6mm thick): relatively rough, with mesh traces of leather processing.

–Thinned to 1.0/1.5/2.0mm: uniform thickness, fiber layer relatively flat.

9 Colors Available

Note

After drum dyeing, The leather without surface treatment, just like hand dye with alcohol dye by ourselves. after drying, there will be a trace of color floating on the surface, this is a normal phenomenon, please gently wipe away.

Leather without color-fixing and anti-fouling treatment is easily contaminated. You can use water-based anti-fouling agent Tan-Kote or powerful color-fixing agent Leather Sheen for anti-fouling.

Tan-Kote, the color will be slightly darker, it feels good, the leather surface has good breathability, and the leather surface can be polished after painting. It is not water-resistant and the anti-fouling layer is not strong.

Leather Sheen does not change color after application, has high film-forming strength, good water resistance, and good anti-fouling and anti-staining effects.

The leather has not been color-fixed. If it is not color-fixed, it will have the characteristics of the original color leather and slowly turn yellow and deepen due to the influence of light, humidity, and temperature.

FINISHED PRODUCT DISPLAY

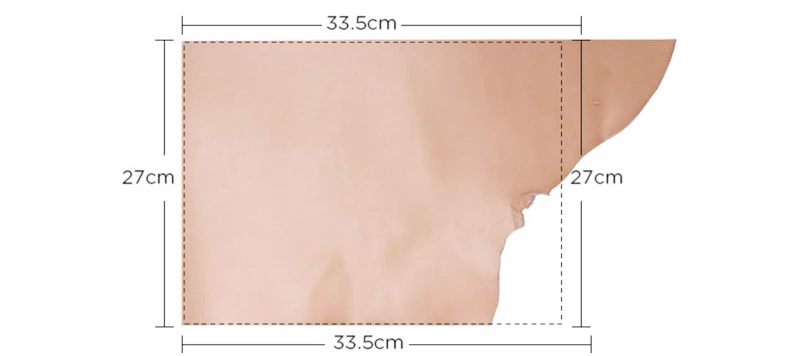

About 1-5 Square Feet Irregular Shape

1 sq.ft irregular form,is equivalent to about 900 cm², The shape is irregular, but all the surface will be calculated. if 3sq.ft irregular,the area is 3×900=2700 cm². and so on…

After the customer make an order, we started to cut the leather, so the size and the shape we ship to you is still uncertain. but we will try our best to send the good piece to you.

If you want to custom size,please send us a message before purchase,we could check we could cut or not.thanks for understand.

About the Defect

Leather pieces are cut from a whole piece of leather,During the growth of a cow ,there are a few blemish such as scratches or scars,narural grain,small holes or wrinkle on it ,But, this leather has been selected to give you a high quality product and should work well for most leathergoods that require a veg tan leather.please comtact us if you are not satisfied with the quality.

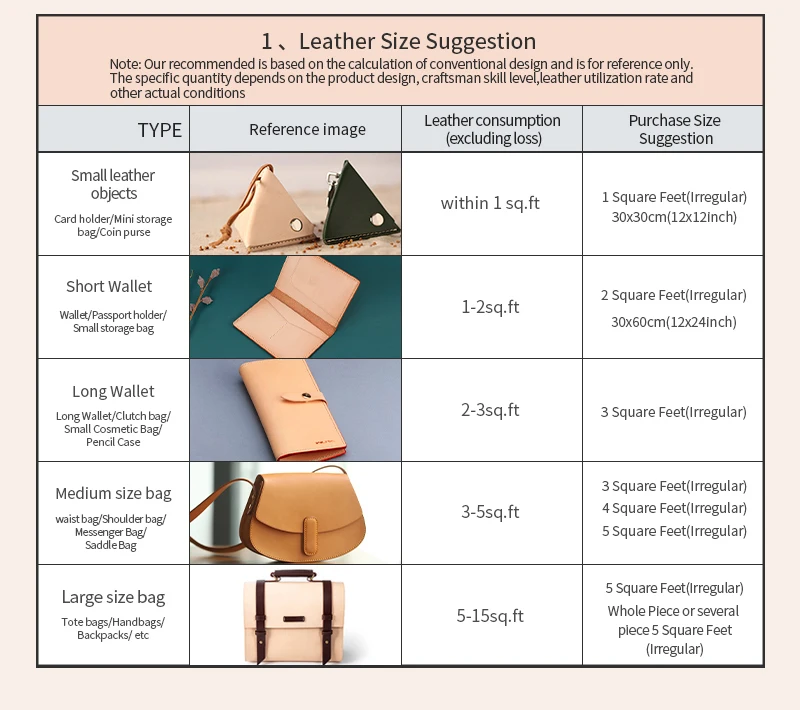

Size & Thickness Suggestion

Reviews

There are no reviews yet.